Contact

Foshan Nanhai FuFeng Electric Equipment Factory

Add.: No.3 Plant, Shatang, Dabu West Village, Lishui Town, Nanhai District, Foshan City, Guangdong Province, ChinaFax: +86-757-81091189

Ice Maker

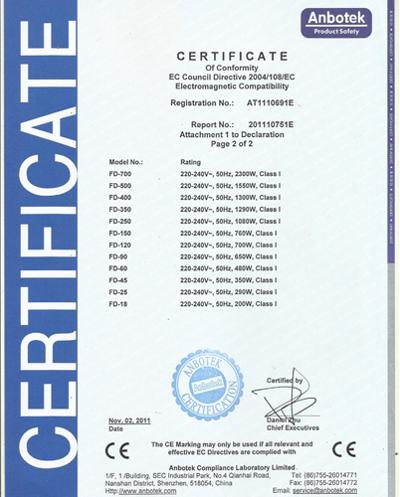

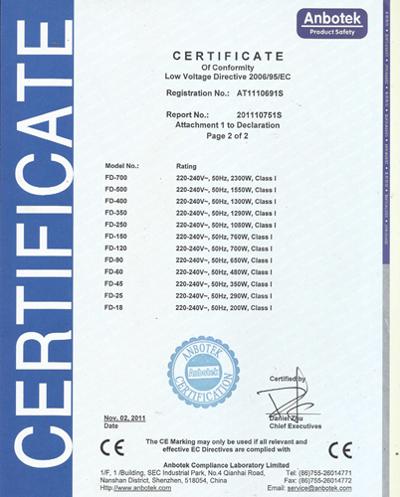

Our company has designed FD series ice maker, which features high efficiency, for customers in Africa, the Middle East and Oceania. The ice machine is divided into two categories depending on its capacity. One is FD-120 series with output ranging from 20 to 120kg in 24 hours, while the other one is FD-150 series, whose yield is greater than 150kg in 24 hours. FD-150 ice maker is usually equipped with compressors such as America Copeland or Italy Aspera, which are characterized by high efficiency, low loss, little noise and long service time.

Our product is highly integrated, thus contributing to easy installation. In addition, it is designed with standard sizes, which reduces space required and also makes it easy and convenient to transfer the ice machine from one place to another. The ice maker also features easy usage since users only need to plug it into an electric power whenever they need ice. Its shell is made of 201 stainless steel. The air inlet is dust proof. Moreover, the separate cover plate features easy assembly and dis-assembly, thus facilitating cleaning. An over-sized thermovent is made use of to quicken heat dissipation as well. It is common that some customers have special requirements for voltage, cooling method and plug types. Hence, we also provide ice machines which can work with power supply with voltage as 110V. Our customers can choose water cooling or air cooling based on what they need. We utilize different plugs on ice makers which work under different circumstances.

Our ice maker comes with an electric control panel, which allows full-automatic ice production with as little as manual interference. In another word, the whole ice production process including water feeding, ice forming and ice shedding is carried out automatically. In this way, contamination can be efficiently eliminated, which further enables users to directly put those small ice particles obtained into beverages. The desired thickness of ice cubes can be altered based on actual conditions. The capacity of our ice maker is about 90 to 95 percent of rated value in summer, while the yield reaches 100 to 130 percent of rated output in the environment where the temperature is lower than 23 degrees Celsius.

Our ice machine is extensively applied to produce ice which is used in beverages or for food refrigeration and food preservation. It is widely adopted in many places at home and abroad, which include bars, Mcdonald's, KFC, milk tea shops, tea cafes, coffee shops, hotels, movie houses, western food restaurants, beverage outlets, Chinese restaurants, leisure food factories, meat processing plants, freezing food factories, fruit-and-vegetable processing plants, spices processing factories, etc.

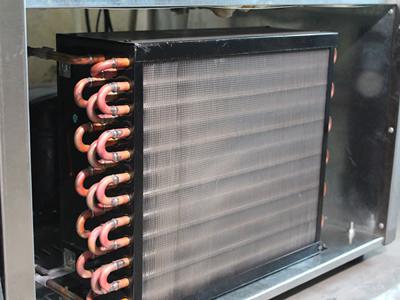

Condensate fan greatly improves heat dissipation efficiency, which further ensures higher stability and higher efficiency of ice formation. In a long term, service life of our ice machine is extended considerably.

The advanced water feed device we adopt enables automatic water feeding when the water in the ice machine is insufficient. Hence, we only need to plug the machine into appropriate power supply to make it work, which is very convenient and simple. Professional-class nickel plated ice cube trays used are able to withstand high temperature difference caused by alternate cooling and heating. Hence, dehydration will be instantly conducted once the temperature is high enough. In addition, the extremely cold bottom plate is of minus 20 degrees Celsius and it speeds up ice forming process. As a result, our ice machine is pretty durable.